Grass Granules

How to make grass pellets?

Biomass pellets have become a more popular fuel in the fuel market. Due to the high efficiency and low ash content, biomass pellets will become the main fuel in the future.

Biomass pellets are made from biomass materials such as wood, grass, rice husk, alfalfa, etc. These raw materials are processed into biomass pellets through a pelletizing machine.

As a kind of biomass pellets, grass pellets have a wide range of applications and unique advantages, not only the market demand is huge, and the price is much higher compared to other pellets. So can we make grass pellets at home? How to turn waste into treasure when raw materials are easily available? Today we give you an introduction to making grass pellets.

Advantages of grass pellets

1. Many raw materials can be made into pellets, and grass pellets as fuel has been the accepted method in Europe. Not only fuel, grass pellets as feed is also a good choice.

2. Grass pellets as biofuel is economic, energy saving, environmental friendly and sustainable. As a clean fuel, more and more people like to choose grass pellets for the reason that the raw material is cheap and easily available.

3. In addition, grass pellets can be used as feed for horses, cattle and many other animals. As a feed, grass pellets can replace part of hay feeding and are rich in nutrients.

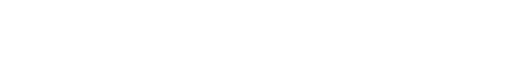

Simple process

The production of grass pellets has great potential as a low-tech, small-scale renewable energy system that can be produced locally, processed locally, and traded locally, while positively impacting agro-pastoral areas. The easy availability of raw materials and the ease of operation of small pellet mills have become more popular choices.

How to make grass pellets?

The process of making grass balls

First of all, we need to choose the right grass pellet mill according to our requirements. As a pellet mill manufacturer, Huayu recommends two kinds of pellet mills for you to choose, XGJ560 and XGJ850, you can choose the right pellet mill according to the actual situation, or you can contact us for more details about the pellet mill equipment!

After choosing the right pellet mill, you can start making your own grass pellets. The key to making grass pellets is to adjust the moisture of the raw material, the optimum moisture of grass pellets is around 15%, you can adjust the moisture by drying it in the sun or using a dryer.

Notes on pellet processing:

1. Operating workers should read the instruction manual carefully and be familiar with each process of the equipment before they get on the machine.

2. The production process should be operated in strict accordance with the regulations and sequential order, and the installation operation should be carried out according to its requirements.

3. The host equipment needs to be installed and fixed on the horizontal cement ground, reinforced tight screws.

4. Smoking and open fire are strictly prohibited in the production site.

5. Each time after the machine is turned on, it needs to idle for a few minutes first, idle to confirm that the pressure wheel fits the mold rotation before feeding.

6. It is strictly forbidden to add stones, metals and other hard debris to the feeding device, and do a good job of removing iron before granulation to avoid damage to the granulation chamber.

7. During the operation of the equipment, it is strictly forbidden to use hands or other tools to dial the material to avoid danger.

8. If there is any abnormal noise during the production process, you need to immediately cut off the power supply, check and deal with abnormalities before turning on the machine to continue production.

9. Before stopping the machine, stop the auxiliary feed first, then put the oil, wait until the die hole is full of oil, no oil in the granulating chamber before stopping. The purpose of putting oil material is to make it easier to discharge material when producing next time.

According to the requirements of the correct operation of the pellet mill, and in accordance with the requirements of attention to matters related to not only improve the output and running performance of the equipment, but also to extend the service life of the equipment.