Wood Trimmings

What is the use of waste wood trimmings?

There are many kinds of wood waste materials, such as: boards, blocks, chips, offcuts, edges, board edges, branches, forks, trunks, construction templates, etc. We can reuse these waste materials, which were previously considered useless, after processing, which can effectively reduce the waste of wood resources and play a very good help for environmental protection.

Wood is a renewable biological resource, the only renewable and recyclable green material and biological resource among the four major materials (steel, cement, wood and plastic) in the world today. At present, the recycling of waste wood trimmings is mainly used in the following areas:

1. Waste wood can be used to make paper. By crushing and processing the material made to process paper, not only can the waste wood be reused, but also can bring economic value. This is a very good solution to waste wood, saving wood resources while playing a protective role for the surrounding environment.

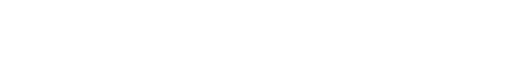

2. Use of waste wood to manufacture wood-based man-made boards. Such as particle board, medium fiber board, gypsum particle board, cement particle board, etc.

3. Use of waste wood to manufacture handicrafts, wood is often made into artwork by handicraft enthusiasts.

4. Use the waste wood to manufacture wood pellets, charcoal, wood vinegar liquid and wood gas.

What are the advantages of making fuel pellets from wood trimmings?

Wood trimmings are the ideal raw material for fuel pellets and have great economic and social value. The following are the advantages of wood trimmings for pellets:

1. Raw material advantages. In large lumber mills, furniture factories, gardens, and wood-related enterprises manufacturing will produce a large number of wood residues. These side materials are large and cheap, in the past often directly pile up decay or landfill, incineration for wood resources is also a serious waste.

2. High combustion value of pellets. The fuel value of processed wood pellets can reach 4500 calories/kg, compared with coal, low ignition point, easy to ignite; increased density, high energy density.

3. The pellets have less harmful substances. When burning, the content of harmful gas components is extremely low, and the emission of harmful gases is less, which has environmental benefits. And the ash after combustion can also be used directly as potash, saving money. And there is very little ash ballast after combustion, which greatly reduces the site for stacking coal ballast and reduces the cost of ballast.

4. Low cost of pellet transportation. Due to the shape of pellets, the volume is compressed, saving storage space, and also easy to transport, reducing transportation costs.

Notes on pellet processing:

1. Operating workers should read the instruction manual carefully and be familiar with each process of the equipment before they get on the machine.

2. The production process should be operated in strict accordance with the regulations and sequential order, and the installation operation should be carried out according to its requirements.

3. The host equipment needs to be installed and fixed on the horizontal cement ground, reinforced tight screws.

4. Smoking and open fire are strictly prohibited in the production site.

5. Each time after the machine is turned on, it needs to idle for a few minutes first, idle to confirm that the pressure wheel fits the mold rotation before feeding.

6. It is strictly forbidden to add stones, metals and other hard debris to the feeding device, and do a good job of removing iron before granulation to avoid damage to the granulation chamber.

7. During the operation of the equipment, it is strictly forbidden to use hands or other tools to dial the material to avoid danger.

8. If there is any abnormal noise during the production process, you need to immediately cut off the power supply, check and deal with abnormalities before turning on the machine to continue production.

9. Before stopping the machine, stop the auxiliary feed first, then put the oil, wait until the die hole is full of oil, no oil in the granulating chamber before stopping. The purpose of putting oil material is to make it easier to discharge material when producing next time.

According to the requirements of the correct operation of the pellet mill, and in accordance with the requirements of attention to matters related to not only improve the output and running performance of the equipment, but also to extend the service life of the equipment.