Palm Granules

As the global economy continues to grow, existing energy resources are increasingly unable to meet the growing demand for fuel, so sustainable fuel resources are being developed to address the problems of fossil fuels, declining forestry resources, and environmental degradation. One of the emerging biomass resources that can solve these problems: palm pellets.

Palm is a versatile plant capable of producing a wide range of biomass. The production of 1 kilogram of palm oil can be accompanied by the production of 4 kilograms of oil palm biomass, and palm biomass and its by-products are seven times more abundant than natural wood. Palm is mainly grown in Southeast Asia, with Malaysia, Indonesia and Thailand ranking among the top three. 7,599,000 hectares of palm were planted in Asia in 2005, producing 146,093,000 tons of fresh bunches and 10,224,000 tons of empty bunches.

Palm empty fruit bunches composition

Palm grains are oily and bulky, composed of cellulose and hemicellulose lignin, containing carbon, hydrogen, nitrogen, sulfur and oxygen, and with a high moisture content of about 65%. The physical properties of palm make them valuable and at the same time make them difficult to be used.

Palm empty fruit bunch utilization

Traditionally, empty fruit bunches are underutilized and are usually used in the following ways:

1. Burning. Their ashes are recycled as fertilizer for plantations, but mass burning is now not allowed.

2. Returned to the field for use as mulch, which not only reduces greenhouse gas emissions but also reduces the need for man-made fertilizers by improving carbon sequestration in the soil organic matter.

3. Some of the empty fruit bunches are sent to landfill.

A large amount of palm biomass energy has been wasted due to limitations in the traditional utilization of palm empty fruit bunches. Now with innovations in palm empty fruit bunch conversion technology, palm biomass can be successfully converted into pellet fuel for blending systems and biomass boilers to generate steam and electricity.

Relevant data show that in 2009, 88.74 tons of palm empty fruit bunches in Asia generated 1714 GWh of off-grid energy at a rate of 20 kWh/ton, for a total off-grid capacity of 357 MW and 400 hours/month.

Palm fiber biomass applications

Granulation of palm fruit skewers

Why do we make palm fruit bunches into pellets? Can't we just put palm biomass into boilers or power plants? The reasons are as follows:

1. In general, the energy content of palm kernel biomass increases when it is converted into pellets.

2. Palm pellet fuel or coal with a calorific value between 4,200 - 4,900 kg cal/kg 28 can be used to replace coal to relieve energy pressure and environmental stress.

3. Palm pellets are sustainable and renewable, can be produced on a large scale and are very friendly to the environment.

4. Palm pellets are dense and clean, easy to transport and store, and the pellets produce very little smoke when burned.

Palm pellet production

A wide range of palm pellets can be made according to the different requirements of consumers. When investing in the production of palm pellets, you can refer to the following suggestions from established palm pellet mills:

1. A comprehensive understanding of the palm pellet production line is necessary.

2. The palm pellet production process should meet the requirements of the target market.

3. The raw material should be sufficient and the continuity of pellet production should be ensured.

4. The quality of raw materials should be guaranteed. The ideal moisture content of raw materials is 15%, and the raw materials should be dried to control the moisture when it exceeds 15%.

5. The location of the palm pellet plant should be convenient for raw material transportation.

6. A feasible survey needs to be conducted in advance.

The processing of palm empty fruit skewers to make pellets

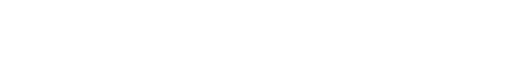

A typical palm granule pellet production line contains the following stages: crushing, drying, grinding, granulation, cooling, screening, dust recovery and packaging.

Usually, the following equipment is involved in the whole palm pellet production line:

1. Electrical cabinet (used to control the equipment in the whole palm pellet production line)

2. Palm crusher (to make palm biomass into a size suitable for drying)

3. Dryer (to control the raw material moisture to meet the pellet making requirements)

4. crusher (grinding the appropriate size and dry material into powder for pelletizing)

5. palm pellet granulator (to make the prepared material into pellets)

6. cooling system (the temperature of the pellets from the granulator is too high and needs to be cooled in order to be packaged)

7. Packing machine (bagging palm pellets)

Notes on pellet processing:

1. Operating workers should read the instruction manual carefully and be familiar with each process of the equipment before they get on the machine.

2. The production process should be operated in strict accordance with the regulations and sequential order, and the installation operation should be carried out according to its requirements.

3. The host equipment needs to be installed and fixed on the horizontal cement ground, reinforced tight screws.

4. Smoking and open fire are strictly prohibited in the production site.

5. Each time after the machine is turned on, it needs to idle for a few minutes first, idle to confirm that the pressure wheel fits the mold rotation before feeding.

6. It is strictly forbidden to add stones, metals and other hard debris to the feeding device, and do a good job of removing iron before granulation to avoid damage to the granulation chamber.

7. During the operation of the equipment, it is strictly forbidden to use hands or other tools to dial the material to avoid danger.

8. If there is any abnormal noise during the production process, you need to immediately cut off the power supply, check and deal with abnormalities before turning on the machine to continue production.

9. Before stopping the machine, stop the auxiliary feed first, then put the oil, wait until the die hole is full of oil, no oil in the granulating chamber before stopping. The purpose of putting oil material is to make it easier to discharge material when producing next time.

According to the requirements of the correct operation of the pellet mill, and in accordance with the requirements of attention to matters related to not only improve the output and running performance of the equipment, but also to extend the service life of the equipment.