Rice Husk Pellets

Properties and uses of rice husk

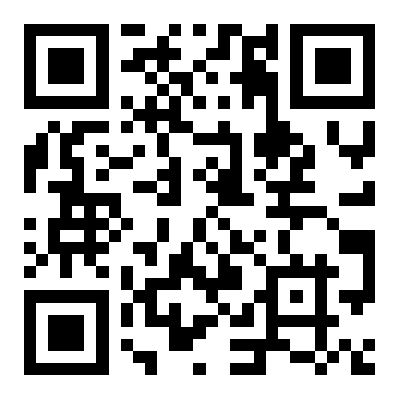

The main components of rice husk vary greatly depending on the variety, origin and processing method. Generally, its water content is about 12%, carbon 36%, nitrogen 0.48%, phosphorus 0.32% and potassium 0.27%. Rice husk contains about 40% crude fiber (including lignin fiber and cellulose) and about 20% five-carbon sugar polymer (mainly hemicellulose). In addition, it contains about 20% ash and a small amount of crude protein, crude fat and other organic compounds.

Uses: Rice husk is a good renewable biomass raw material, which can be processed into fuel pellets through pelletizing machine, transformed into rice husk gas through gasification, direct combustion to produce steam or heat for power generation, heating, etc. Rice husk can also be used to make high quality activated carbon, adsorbent, carbon black, silicon dioxide, silicon carbide, potassium silicate and other chemical products. Compared to oil, natural gas and coal, rice hulls are renewable as a biomass resource, and in 1971 the Food and Agriculture Organization of the United Nations predicted that the most practical use of rice hulls would be to provide energy as fuel.

Rice husk accounts for 20% of the weight of rice grains. Globally, 100 million tons of rice husk are produced annually, of which 70% is underutilized. With demand for rice expected to reach 780 million tons by 2022, more rice hulls will need to be disposed of. Learn more about Rice Knowledge International Rice Research Institute.

Advantages of rice husk pellets

After rice husk is pressed into pellets, the bulk density is greatly increased, making it easy to transport and store in large quantities.

Rice husk pellets are cleaner when burned. Before pellets are made, 15-16% of ash is left behind when rice husk is burned. After pellet making, the ash content is only about 6-7%.

The calorific value of rice husk pellets can be burned fully and efficiently at 3200-3500 calories, which is moderate and suitable for large boilers.

The rice husk pellet machine turns rice husk into treasure and brings economic and social benefits to farmers.

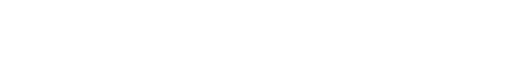

Processing process of rice husk pellets

Sifting . Remove impurities in the rice husk, such as rocks, iron pieces, etc.

Pelletizing. The treated rice hulls are conveyed to the silo, through which they are conveyed to the pelletizer for pelletizing.

Cooling. After pelletizing, the temperature of rice husk pellets is very high and needs to be cooled down in the cooler to keep the shape.

Packaging. If you sell rice hull pellets, you will need a packaging machine to package the pellets.

Rice husk pellet processing process diagram

Notes on pellet processing:

1. Operating workers should read the instruction manual carefully and be familiar with each process of the equipment before they get on the machine.

2. The production process should be operated in strict accordance with the regulations and sequential order, and the installation operation should be carried out according to its requirements.

3. The host equipment needs to be installed and fixed on the horizontal cement ground, reinforced tight screws.

4. Smoking and open fire are strictly prohibited in the production site.

5. Each time after the machine is turned on, it needs to idle for a few minutes first, idle to confirm that the pressure wheel fits the mold rotation before feeding.

6. It is strictly forbidden to add stones, metals and other hard debris to the feeding device, and do a good job of removing iron before granulation to avoid damage to the granulation chamber.

7. During the operation of the equipment, it is strictly forbidden to use hands or other tools to dial the material to avoid danger.

8. If there is any abnormal noise during the production process, you need to immediately cut off the power supply, check and deal with abnormalities before turning on the machine to continue production.

9. Before stopping the machine, stop the auxiliary feed first, then put the oil, wait until the die hole is full of oil, no oil in the granulating chamber before stopping. The purpose of putting oil material is to make it easier to discharge material when producing next time.

According to the requirements of the correct operation of the pellet mill, and in accordance with the requirements of attention to matters related to not only improve the output and running performance of the equipment, but also to extend the service life of the equipment.