Activated Carbon Granules

The role and classification of activated carbon particles

Granular activated carbon is divided into fixed and unshaped granules. It is mainly made of coconut shell, fruit shell and coal as raw materials and refined by a series of production processes. The products are widely used in drinking water, industrial water, brewing, waste gas treatment, decolorization, desiccant, gas purification and other fields. Granular activated carbon is made of high quality anthracite coal, refined and processed by advanced technology, with developed pore structure, good adsorption performance, high mechanical strength, easy to regenerate repeatedly, low cost, etc. It is used in the purification of toxic gases, waste gas treatment, industrial and domestic water purification treatment, solvent recovery, etc.

It is usually divided into powdered activated carbon, irregular granular activated carbon and columnar granular activated carbon according to external shape. Powdered activated carbon is mostly wood-based activated carbon, which fails to meet the standards of some industries due to the problems of easy clogging of the filter surface and difficult separation of powder. Irregular granular activated carbon has a certain shape, high mechanical strength and low dust pollution, so it has advantages in preparation, storage and use, while columnar granular activated carbon particles make up for the problems of easy clogging of the filter surface and difficult separation of powder in powdered activated carbon particles, and have the advantages of high mechanical strength of irregular activated carbon particles and low dust pollution, so it is easy to meet the special requirements of different industries.

Preparation of raw materials

The raw materials for the preparation of activated carbon are very wide, and all the carbon containing materials can be used as raw materials for the preparation of activated carbon, which can also be used for the preparation of granular activated carbon. Coal-based raw materials include anthracite, coal sludge, lignite, petroleum coke and coal-based materials; wood-based raw materials include walnut shells, wood, fruit shells, bamboo, crop straw and carbon residues. In addition, good quality granular activated carbon can also be prepared by using raw materials such as separated carbon powder from dust ash and waste polystyrene foam.

Columnar activated carbon product introduction

Appearance: gray-black, cylindrical, odorless.

Features: Woody columnar activated carbon is made of high quality wood chips and coconut shells, which are crushed, mixed, extruded, shaped, dried, carbonized and activated.

Advanced: Because of using high quality wood chips and coconut shell as raw materials, the columnar activated carbon made is lower in ash, less impurities and gas phase adsorption value than the traditional coal columnar carbon. The pore size of the product is reasonably distributed to achieve huge adsorption and desorption, thus greatly improving the service life of the product (2-3 years on average), which is 1.4 times that of ordinary coal-based carbon.

Originality: woody columnar activated carbon adopts the proprietary technology of non-bonded forming activated carbon. It changes the traditional method of molding with coal tar, starch and other traditional binders. It does not contain binder, but relies entirely on the affinity between carbon molecules and the special nature of the raw material itself. It is made by scientific formula, effectively avoiding the blockage of carbon pores and giving full play to the adsorption function of rich and developed carbon pores.

Applicability:

①, gas phase adsorption

②, organic solvent recovery (benzene gas toluene, xylene, acetone recovery in the acetate fiber industry)

③, impurities and harmful gas removal, waste gas recovery

④, refineries, gas stations, oil depots excess gasoline recovery.

Product advantages:

1. The service life is 4-5 times of ordinary coal activated carbon.

2. High adsorption and desorption, thus greatly improving the recovery rate of solvent.

3. High strength and low ash content, reasonable pore size distribution.

4. High cost performance, suitable for such places with organic gas recycling.

5. High ignition point is safe to use.

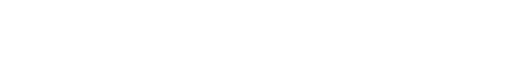

Production process of activated carbon granules

Pelletizing - conveying - cooling - storage - packaging

The pulverized coal enters the buffer bin through the screw conveyor, and then enters the mixer after being measured by the volumetric closed quantitative feeder. The coal powder, coal tar and water are mixed evenly in the mixer in a certain ratio, and then enter the activated carbon granulator for granulation. The formed column-shaped activated carbon granulator is sent to the dryer through the belt conveyor and to the cooler through the skirt belt conveyor, and after cooling, it can be sent to the buffer bin for packaging.

Notes on pellet processing:

1. Operating workers should read the instruction manual carefully and be familiar with each process of the equipment before they get on the machine.

2. The production process should be operated in strict accordance with the regulations and sequential order, and the installation operation should be carried out according to its requirements.

3. The host equipment needs to be installed and fixed on the horizontal cement ground, reinforced tight screws.

4. Smoking and open fire are strictly prohibited in the production site.

5. Each time after the machine is turned on, it needs to idle for a few minutes first, idle to confirm that the pressure wheel fits the mold rotation before feeding.

6. It is strictly forbidden to add stones, metals and other hard debris to the feeding device, and do a good job of removing iron before granulation to avoid damage to the granulation chamber.

7. During the operation of the equipment, it is strictly forbidden to use hands or other tools to dial the material to avoid danger.

8. If there is any abnormal noise during the production process, you need to immediately cut off the power supply, check and deal with abnormalities before turning on the machine to continue production.

9. Before stopping the machine, stop the auxiliary feed first, then put the oil, wait until the die hole is full of oil, no oil in the granulating chamber before stopping. The purpose of putting oil material is to make it easier to discharge material when producing next time.

According to the requirements of the correct operation of the pellet mill, and in accordance with the requirements of attention to matters related to not only improve the output and running performance of the equipment, but also to extend the service life of the equipment.