Sugarcane Bagasse Granulation

Growth and distribution of sugarcane

Sugarcane is a tall, solid perennial herb. Rhizome stout and well developed. Culms 3-5(-6) m tall. The distribution of sugarcane is mainly between 33°N latitude and 30°S latitude, with a relatively concentrated area between 25°N and N latitude. Originally from India, sugarcane is now widely grown in tropical and subtropical regions. The largest area of sugarcane is planted in Brazil, followed by India, and China is in the third place. Other countries with large planting areas include Cuba, Thailand, Mexico, Australia and the United States.

The main cane producing areas in China are mainly located in the tropical and subtropical regions south of 24°N, including 12 southern provinces and autonomous regions such as Guangdong, Taiwan, Guangxi, Fujian, Sichuan, Yunnan, Jiangxi, Guizhou, Hunan, Zhejiang, Hubei, Hainan, etc. Since the mid-1980s, China's cane sugar producing areas have rapidly shifted to the western regions such as Guangxi and Yunnan, and by 1999, Guangxi and Yunnan provinces' cane sugar production has accounted for 70.6% of the country (excluding Taiwan Province). With the development of production technology, there are also decentralized greenhouse plantations in the central plains of mainland China (e.g., Henan, Shandong, Hebei, etc.)

Due to its high calorific value of 3400 to 4200 calories and low ash content, bagasse pellets are popular.

Why use bagasse pellets

In the sugarcane industry, there are many sugar mills in Southeast Asia. For every 10 tons of crushed sugarcane, a sugar mill produces nearly 3 tons of wet bagasse. How bagasse is handled is becoming increasingly important. Few mills burn bagasse fiber as fuel, and when burned in large quantities, it produces enough heat to meet all the needs of a typical sugar mill. The remaining bagasse can be processed into biomass pellets, which can be used as feedstock for bagasse pulping and exported abroad as fuel, which can bring economic benefits to the mills.

Advantages of bagasse pellets

Bagasse pellets are used in many places because of their convenience and comfort, and it has the following advantages:

1、High return on investment

Low cost of raw materials, small investment in equipment and simple operation. Ordinary people can operate the equipment after simple training, the labor cost is extremely low, and the coal price is volatile. These factors ensure a better return on investment.

2、Wide range of applications

Bagasse pellets are easy to use and store. It can be used for heating, living stoves, hot water boilers, industrial boilers, biomass power plants, etc. to replace firewood, coal, fuel oil and LPG. Family units are also applicable; good combustion effect can meet the needs of cooking, heating and bathing, especially the necessities of life in biomass power plants.

3、Environmental benefits

Bagasse pellets are good for the environment; bagasse pellets are carbon neutral, which means that the carbon dioxide emissions it produces during growth are absorbed by itself. They do not release other air polluting gases into the air.

4. Renewable

Unlike fossil fuels such as coal and natural gas, which are consumptive (take a long time to form), bagasse pellets are renewable because sugarcane grows every year and we can have a constant supply of raw materials.

5、Turning waste into treasure

In the background of global energy shortage, bagasse pellets are the representative of turning "waste" into wealth, and sugarcane is fully utilized, besides, it also increases the income of farmers.

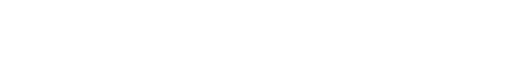

Sugarcane bagasse pellet production process

In order to generate enough thermal energy to meet all the needs of a typical sugar mill or profitably by making pellets. In general, bagasse pellets are produced in several steps:

1. Crushing: The raw material is crushed into a powder with a particle size of 3-5mm using a high efficiency crusher.

2. Drying: The moisture of fresh bagasse is about 48-50%, ensure that the moisture of bagasse is dried to 10-15% to make the bagasse solidify. Use drum dryer for drying.

3. Pelletizing: The bagasse powder material is fed into the biomass pellet mill, where they will be compressed into pellets by the movement of the die and a set of rollers inside the mill.

4. Cooling: The pellet cooler This unit can save floor space and processing time. Cooling the pellets can make them easier to pack and transport.

5. Packing: Bio-pellet ton bag packing machine After the pellets are cooled, they are packed in a packing machine for easy storage and transportation.

Notes on pellet processing:

1. Operating workers should read the instruction manual carefully and be familiar with each process of the equipment before they get on the machine.

2. The production process should be operated in strict accordance with the regulations and sequential order, and the installation operation should be carried out according to its requirements.

3. The host equipment needs to be installed and fixed on the horizontal cement ground, reinforced tight screws.

4. Smoking and open fire are strictly prohibited in the production site.

5. Each time after the machine is turned on, it needs to idle for a few minutes first, idle to confirm that the pressure wheel fits the mold rotation before feeding.

6. It is strictly forbidden to add stones, metals and other hard debris to the feeding device, and do a good job of removing iron before granulation to avoid damage to the granulation chamber.

7. During the operation of the equipment, it is strictly forbidden to use hands or other tools to dial the material to avoid danger.

8. If there is any abnormal noise during the production process, you need to immediately cut off the power supply, check and deal with abnormalities before turning on the machine to continue production.

9. Before stopping the machine, stop the auxiliary feed first, then put the oil, wait until the die hole is full of oil, no oil in the granulating chamber before stopping. The purpose of putting oil material is to make it easier to discharge material when producing next time.

According to the requirements of the correct operation of the pellet mill, and in accordance with the requirements of attention to matters related to not only improve the output and running performance of the equipment, but also to extend the service life of the equipment.