Peanut Shell Pellets

Peanut shells turned into treasure

Peanut shells are waste? No, statistics show that peanut shells make up about 20% of the weight of dry peanut pods. It may be a raw material for a new energy material, using peanut shells to make pellets customers to replace coal as an important fuel. How to discover your own peanut fuel treasures from the waste?

Peanuts and peanut shells

Peanut, formerly known as groundnut (scientific name: Arachis hypogaea Linn.), is a nut that is abundant in production and widely consumed, also known as "everlasting fruit", "mud bean", "fava bean", etc, "bean" and so on. Genus Rosaceae, leguminous annual herbs, stems erect or prostrate, 30-80 cm long, pterygoid and keel valves separate, pods 2-5 cm long, 1-1.3 cm wide, swollen, thick pods, flowering and fruiting period of June to August. Mainly distributed in Brazil, China, Egypt and other places. There are various types of peanuts around the world, characterized by branching habit and branch length. The large amount of peanut production has left an abundance of peanut waste, such as peanut shells and peanut fiber, which is now considered a potential fuel source.

The value of peanut shells

After harvesting and shelling, peanut shells, or shells separated from the nuts, account for about 20% of the weight of dry peanut pods, which means that a large amount of shell residue biomass is left after processing. Peanut shells are used as cattle feed, poultry litter and garden mulch, and they are now considered as a potential fuel source.

Composition of peanut shells

Although the composition of peanut shells varies by variety, the main chemical composition of peanut shells does not change significantly by variety. The main components of peanut shells are 37.0% cellulose, 28.8% lignin, 8.2% protein, and 2.5% carbohydrates. The composition of peanut shells makes peanuts a treasure in disguise, both for fuel and for feed production.

Peanut shell fuel pellets

In order to make full use of peanut shells and develop new energy, peanut shell pellet mill can be used to press peanut shells into fuel pellets. There are two kinds of peanut shell pellet making machines: flat die and ring die. The former is usually used for small-scale pellet production and is favored by home users and farmers, while the latter is used for large-scale production of pellets, medium-sized and large pellet producers for large boilers and power generation.

Advantages of peanut shell pellets

Peanut shells used directly as fuel are bulky, have low combustion rates and are difficult to transport. Granulation of peanut shells will greatly improve their storage and logistics, and peanut shell pellets have the following advantages:

High-density peanut shell pellets can be ignited quickly, with good combustion performance, high combustion efficiency and less ash produced.

Peanut shells are a common raw material and easily available. This will reduce the production cost of peanut shell pellets and provide a larger profit margin.

Peanut pellet fuel is a green biomass energy source with low emissions and friendly environment.

Due to high combustion rate and easy storage, peanut shell pellets can be widely used for residential heating and daily energy supply, as well as for industrial boilers to generate electricity.

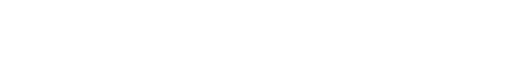

The production process of peanut shell pellets and the equipment used

The biomass pellet mill pelletizes the prepared material into pellets. This step is the heart of the entire production line, so the stability and high productivity of the pellet mill is a top priority for the customer.

The pellet cooler cools the newly extruded hot pellets and hardens them. The process after the pellet mill is to cool the pellets, by natural cooling is too slow and uneven, using professional pellet cooler is necessary.

Bio-pellet tonnage packaging equipment Pack the pellets as required, either in small packages or in tonnage packages.

Conveying equipment, which is placed at the front and back of the main machine to help transport the raw materials in the production process

Electrical control cabinet, which controls the power of all the equipment of the whole production line

The pellet mill, as the core of pellet production, determines the quality of the bamboo material of the whole production line. YULONG vertical ring die biomass fuel pellet mill is very suitable and highly recommended for its adaptability, easy operation and convenient maintenance.

For large-scale pellet production, the vertical ring die pellet mill is recommended because of its high production capacity.

Notes on pellet processing:

1. Operating workers should read the instruction manual carefully and be familiar with each process of the equipment before they get on the machine.

2. The production process should be operated in strict accordance with the regulations and sequential order, and the installation operation should be carried out according to its requirements.

3. The host equipment needs to be installed and fixed on the horizontal cement ground, reinforced tight screws.

4. Smoking and open fire are strictly prohibited in the production site.

5. Each time after the machine is turned on, it needs to idle for a few minutes first, idle to confirm that the pressure wheel fits the mold rotation before feeding.

6. It is strictly forbidden to add stones, metals and other hard debris to the feeding device, and do a good job of removing iron before granulation to avoid damage to the granulation chamber.

7. During the operation of the equipment, it is strictly forbidden to use hands or other tools to dial the material to avoid danger.

8. If there is any abnormal noise during the production process, you need to immediately cut off the power supply, check and deal with abnormalities before turning on the machine to continue production.

9. Before stopping the machine, stop the auxiliary feed first, then put the oil, wait until the die hole is full of oil, no oil in the granulating chamber before stopping. The purpose of putting oil material is to make it easier to discharge material when producing next time.

According to the requirements of the correct operation of the pellet mill, and in accordance with the requirements of attention to matters related to not only improve the output and running performance of the equipment, but also to extend the service life of the equipment.