Bamboo Pellets

Bamboo properties and uses

Bamboo is considered to be a promising renewable resource. The advantages of bamboo are fast growth rate, easy processing, good mechanical properties, low cost and wide range of uses.

Bamboo is a natural choice for biomass energy production. Bamboos are members of the grass family, even though they are essentially woody. There are about 1250 species of bamboo in the world, ranging from 10-40 cm in height. Bamboo can be harvested four times a year and covers millions of hectares worldwide, which means that it is a potentially sustainable biomass fuel or raw material.

Bamboo is already widely used in everyday life. Bamboo has been used for general construction, paper and textile production, handicraft production, food production, furniture production and biomass energy production. In addition, bamboo is a promising renewable resource due to its fast growth rate, simple processing, good mechanical properties, low cost, and wide range of uses.

Composition of bamboo

The constituent elements of bamboo are suitable for pressing pellets.

As one of the important biomass resources, bamboo is widely distributed, fast-growing and versatile, and has a high utilization value in biomass-based energy and materials. The results showed that the total mass fraction of cellulose, hemicellulose, and lignin in moso bamboo was about 70%, with the content of cellulose and hemicellulose yarn being 48%~55.7%. Since these two are more easily degraded than lignin, moso bamboo is a good raw material for further conversion. By comparing the composition of moso bamboo in different growth periods, it was found that the chemical composition of 1, 2 and perennial moso bamboo did not change much, indicating that moso bamboo can grow to maturity in a short period of time (1 year) and has a very optimistic prospect as a renewable raw material.

It also has good mechanical properties, which means that bamboo can be easily processed into pellets by a pellet mill. Dried bamboo has a calorific value of about 16 MJ/kg and a moisture content of about 13%. The fixed carbon content is about 15%, while the volatile matter content is almost up to 80%. The above properties make bamboo comparable to woody materials and superior to crop residues, such as grass and straw.

The inorganic ash content of biomass pellets depends on the composition of the mineral components in the source fuel and the combustion process. The ash-forming elements are mainly Na, Mg, Si, Al, Fe, Ca, Na, K, Zn and Ti.

The value of bamboo as a biomass energy source

Bamboo is considered to be a new energy source. Biomass fuel processed from bamboo has a low calorific value of about 4400-4500 calories/kg and an ash content of about 0-1% similar to or slightly higher than beech, spruce, eucalyptus, etc . The fuel pellets made from this material can be used for fireplaces and stoves.

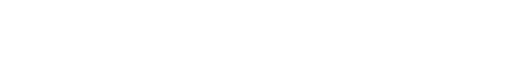

Production process of bamboo pellets

The bamboo residue transported to the pellet mill is crushed into appropriate size, and the processed bamboo chips are dried and sent to the bamboo pellet mill to be pressed into pellets. The newly extruded bamboo pellets are cooled and cured into solid and enhanced strength, while the bamboo pellets and bamboo chips are separated by sieving, and then packaged for storage or transportation.

The equipment involved in the production of bamboo pellets

Electric control cabinet (control the power equipment of the whole production line)

Tyrone pulverizer pulverizes the proper size and dried material into powder for granulation.

Drum dryer Drying raw materials to the moisture range required for pelletizing

Biomass pellet mill Granulating the prepared material into pellets

Pellet cooler to cool the newly extruded hot pellets and harden them

Bio-pellet tonnage packaging equipment (pellets can be packaged in small or tonnage packages as required.

Conveying equipment (placed at the front and back end of the main machine to help transport the raw material in the production process)

The pellet mill, as the core of bamboo pellet production, determines the quality of the bamboo material of the whole production line. YULONG vertical ring die biomass fuel pellet mill is very suitable and highly recommended for its adaptability, simple operation and easy maintenance.

For large-scale bamboo pellet production, the vertical ring die pellet mill is recommended because of its high production capacity.

If you have an abundant source of bamboo, this is an opportunity to make bamboo pellet fuel for home use or profit through a pellet mill.

Notes on pellet processing:

1. Operating workers should read the instruction manual carefully and be familiar with each process of the equipment before they get on the machine.

2. The production process should be operated in strict accordance with the regulations and sequential order, and the installation operation should be carried out according to its requirements.

3. The host equipment needs to be installed and fixed on the horizontal cement ground, reinforced tight screws.

4. Smoking and open fire are strictly prohibited in the production site.

5. Each time after the machine is turned on, it needs to idle for a few minutes first, idle to confirm that the pressure wheel fits the mold rotation before feeding.

6. It is strictly forbidden to add stones, metals and other hard debris to the feeding device, and do a good job of removing iron before granulation to avoid damage to the granulation chamber.

7. During the operation of the equipment, it is strictly forbidden to use hands or other tools to dial the material to avoid danger.

8. If there is any abnormal noise during the production process, you need to immediately cut off the power supply, check and deal with abnormalities before turning on the machine to continue production.

9. Before stopping the machine, stop the auxiliary feed first, then put the oil, wait until the die hole is full of oil, no oil in the granulating chamber before stopping. The purpose of putting oil material is to make it easier to discharge material when producing next time.

According to the requirements of the correct operation of the pellet mill, and in accordance with the requirements of attention to matters related to not only improve the output and running performance of the equipment, but also to extend the service life of the equipment.