Alfalfa grass pellets

How to pelletize alfalfa grass?

Alfalfa grass is known as the "king of forage grass". Alfalfa grass has the advantages of high yield, high protein and high quality. Fresh alfalfa grass has a lot of water, which can promote the digestion and excretion of cattle. In practical needs, people use alfalfa hay or alfalfa pellets as feed for other animals such as cattle, goats and horses, so which one is more suitable for animal feeding?

Even though alfalfa hay and alfalfa pellets have the same nutritional value, there are differences in their functions. As a high quality roughage, alfalfa hay usually piles up residue during the feeding process, which causes a lot of waste. In addition, some animals do not like to eat hay because there will be alfalfa powder inhaled into the nasal cavity, so making alfalfa hay pellets will be able to avoid these problems very well.

What are the advantages and disadvantages of alfalfa pellets? How to make alfalfa pellets? How to choose the right alfalfa pellet machine? As a professional biomass energy equipment manufacturer, Huayu will provide you with detailed answers, please find your answers in the article!

Advantages and disadvantages of alfalfa pellets

Advantages:

1. Easy to store and transport. Alfalfa pellets are small in size, light in weight and low in water absorption.

2. Avoid animals' picky diet and reduce food waste.

3. It has good palatability and increases the feeding quantity.

Disadvantages

1. It is known that alfalfa grass is rich in nutrients, and the possibility of skin inflammation after sun exposure will increase when animals eat too much.

2. It causes intestinal flatulence, especially for ruminants like cattle or sheep.

How to make alfalfa pellets?

How to make alfalfa pellets? Huayu pellet mill can help you to make pellets from dewatered alfalfa hay easily!

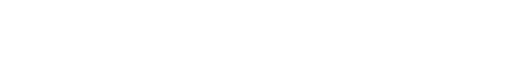

First, prepare your alfalfa pellet maker. If it is just for your own use at home, a small pelleting machine is enough, if it is a pellet mill, you can use a large machine and related auxiliary equipment.

Next, prepare the dryer. It is well known that wetter or drier material affects the final quality of the biomass pellets, so you need a dryer to control the moisture content, which is optimally around 15%.

Third, prepare the grinder to grind the alfalfa grass to a size suitable for making alfalfa pellets.

Finally, use a pelletizer to compress the alfalfa grass powder to make pellets.

How to choose a feed pellet mill?

For some beginners: you may be confused about how to choose the right pellet mill, the following may be helpful.

1. Choose a reliable pellet mill manufacturer or supplier

You can evaluate the manufacturer from the following aspects to make sure it is a real manufacturer and not a middleman.

(1) Inquire whether there is a perfect after-sales service

(2) Check the service life and delivery time of wearing parts.

2. Choose the right pellet mill according to your situation

Different livestock need different pellet sizes, for example chickens and fish need fine feed, while sheep need more coarse grains. You can choose the right pellet mill according to different dies.

3. Productivity

Generally speaking, we recommend you to choose a pellet mill with higher production rate than the demand. Wear and tear of the die is an unavoidable problem, which may lead to lower production, so the pellet mill with high production rate is more secure for the demand.

4. Auxiliary equipment

The moisture and size of the raw material are key factors affecting the final quality of the pellets, so you may also need related auxiliary equipment, such as: dryers, crushers, coolers and packaging machines.

Notes on pellet processing:

1. Operating workers should read the instruction manual carefully and be familiar with each process of the equipment before they get on the machine.

2. The production process should be operated in strict accordance with the regulations and sequential order, and the installation operation should be carried out according to its requirements.

3. The host equipment needs to be installed and fixed on the horizontal cement ground, reinforced tight screws.

4. Smoking and open fire are strictly prohibited in the production site.

5. Each time after the machine is turned on, it needs to idle for a few minutes first, idle to confirm that the pressure wheel fits the mold rotation before feeding.

6. It is strictly forbidden to add stones, metals and other hard debris to the feeding device, and do a good job of removing iron before granulation to avoid damage to the granulation chamber.

7. During the operation of the equipment, it is strictly forbidden to use hands or other tools to dial the material to avoid danger.

8. If there is any abnormal noise during the production process, you need to immediately cut off the power supply, check and deal with abnormalities before turning on the machine to continue production.

9. Before stopping the machine, stop the auxiliary feed first, then put the oil, wait until the die hole is full of oil, no oil in the granulating chamber before stopping. The purpose of putting oil material is to make it easier to discharge material when producing next time.

According to the requirements of the correct operation of the pellet mill, and in accordance with the requirements of attention to matters related to not only improve the output and running performance of the equipment, but also to extend the service life of the equipment.